THERE’S A CATCH!

An Eyepiece - Adapter Compatibility Study

by Ray Taylor 11-11-15

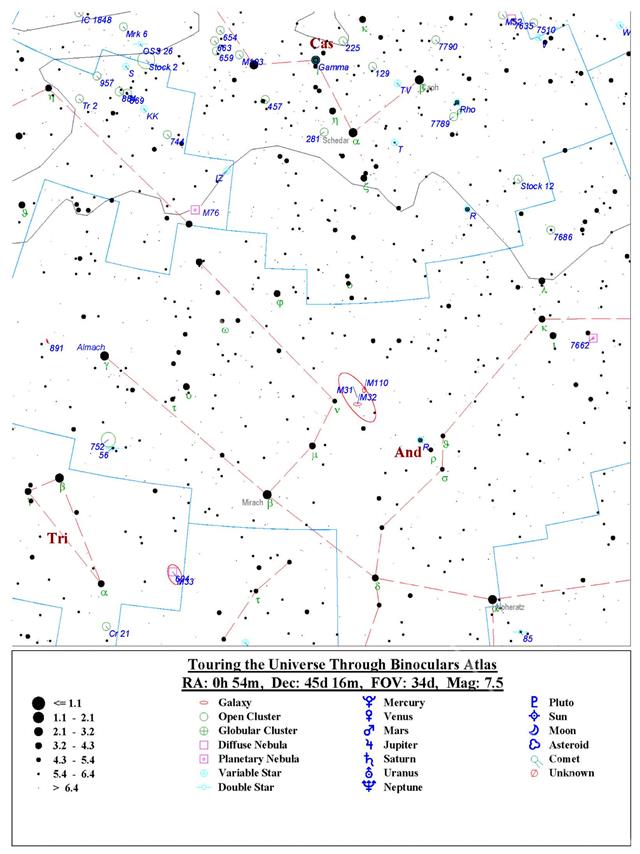

For at least 10 years, observers have complained in forums about eyepiece barrel undercuts causing various problems, but especially catches. Because of my own experiences with catches occurring during insertion or extraction of an eyepiece when used with an adapter, I decided to do some investigation as to why. Catches, I found, are not a one sided issue.

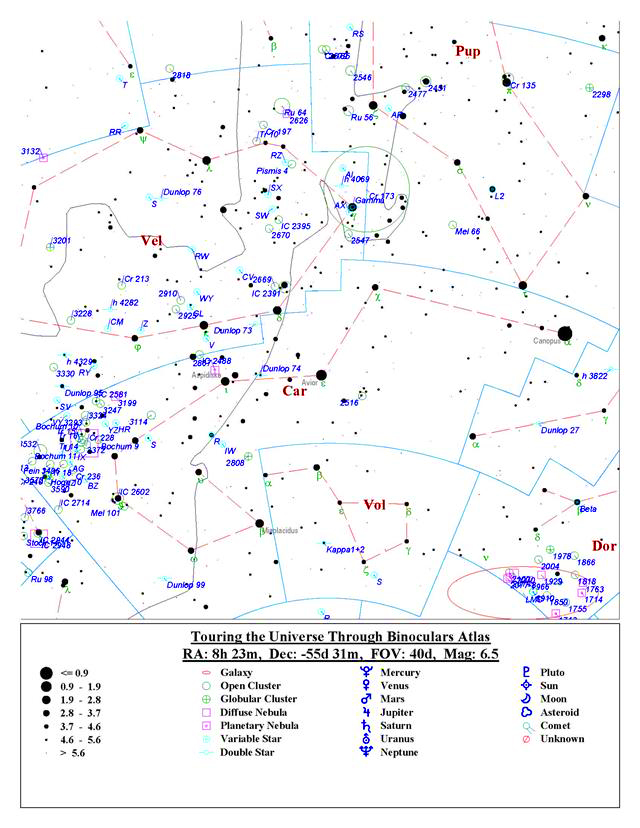

![]() |

| This photo distinguishes the various forms of undercuts with one possible remedy for those who are troubled with catches. These eyepieces were used as part of the testing process. |

HISTORY

For many decades, eyepiece barrels were made smooth. A single thumbscrew was employed in the adapter or focuser to tighten or clamp the eyepiece in place. A very short rotation, just a few degrees, of the thumbscrew was sufficient to tighten or release an eyepiece barrel.

An eyepiece maker then cut a groove (referred to here as an “undercut”) into the circumference of the eyepiece barrel where the thumbscrew comes to rest. This was designed to ensure that the eyepiece remained in place even if the thumbscrew was slightly loosened because the tip of the screw would remain within the confines of the undercut, even if the eyepiece slipped. The only intent of the barrel undercut was to prevent an unintended eyepiece ejection. Unscrewing the thumbscrew less than one rotation would usually release the eyepiece. The number of degrees of thumbscrew rotation for tightening or loosening was slightly increased from that required by a smooth barrel because of the extra depth of the undercut.

Older 1.25” adapters employed a smooth bore and single thumbscrew. Some years after the undercut was made popular for use with thumbscrews, a telescope/focuser maker added a metal compression ring (usually brass) to the inside of the adapter. This ring is inset in a groove, milled inside the 1.25” bore and is necessarily close to the top of the adapter because that is where the thumbscrew must be located. In this arrangement, the thumbscrew applies pressure to the brass ring, which in turn presses against the eyepiece. The sole purpose of the metal compression ring is to prevent thumbscrew dimples on the eyepiece barrel; preventing aesthetic marring of the barrel. The compression ring does not grasp the circumference of the eyepiece; the thumbscrew is still the mechanism for clamping the eyepiece against the opposing inside wall of the adapter. The pressure applied by the thumbscrew on the eyepiece barrel is spread very little by the malleable, thin brass ring. Holding power or grasping strength is still determined by the tightness of the thumbscrew. To work most effectively, the compression ring and the undercut must align perfectly.

More recently, new adapters have been designed using a collet mechanism instead of a thumbscrew to hold an eyepiece. A collet eyepiece adapter changes the direction of pressure that is applied. By rotating a threaded collar, downward force is applied at the top of a rigid split ring which is forced down upon a bevel. The bevel engagement forces the ring to compress, changing the direction of force inward to tighten against the eyepiece barrel. The collar threads, but mainly, the angle of the bevel, determine how fast pressure is applied by the compression ring to the eyepiece barrel. Because the bevel is at one end of the compression ring, the split compression ring must be very rigid to provide relatively even pressure from the top to the bottom of the ring’s contact with the eyepiece barrel. Other recent collet style adapters have been designed using a bevel at both the top and bottom of the compression ring. Still others use the collet system to apply pressure through encapsulated plastic or metal pins to hold the eyepiece barrel. The collet mechanism has been employed for many decades in metal machining and woodturning tools.

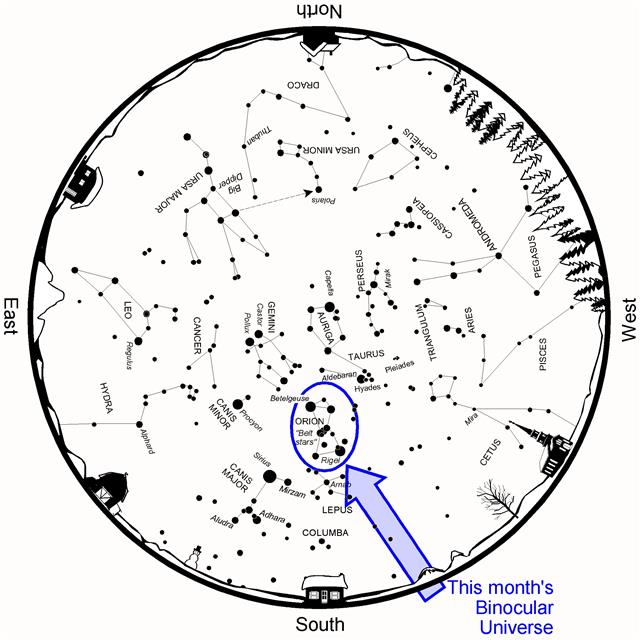

![]() |

| These are the ten adapters used during the testing process. Although they are all designed to hold a 1.25” eyepiece, some adapters have an edge at eliminating catches. |

A few eyepiece makers have supplanted the barrel undercut with an inverted conical taper, cut into the top of the eyepiece barrel. I have not read any technical data concerning this mechanism when used with existing adapter designs, but advertising claims that it prevents catches. I will explain some inherent mechanical issues when I discuss advantages and problems.

In an attempt to mitigate catches, two companies who formerly used barrel undercuts, have eliminated them on new eyepiece barrels; and at least one company now uses smooth barrels on some models and barrels with undercuts on other models.

There has been a slow progression of change in both eyepiece barrels and adapters over the past 40 years or so. It is important to note that optics designers often have no control over how an adapter might be designed… just as telescope and focuser manufacturers may have no control over how an optical designer builds a new eyepiece. This means that the various “improvements” in the design of adapters and eyepiece barrels, have been created without necessarily considering how they would perform together. Each new feature might actually work very well when isolated, but may not work with other features equally well.

CATCH CAUSES

Almost all catches are caused by a single issue. They occur when two opposing right-angle shoulders contact each other. On eyepiece barrels with no undercut, there is one shoulder; it is the base of the eyepiece barrel. On an eyepiece with an undercut there are 3 shoulders; the barrel base and each side of the undercut, described here as the lower shoulder (closest to the bottom of the eyepiece barrel) and the upper shoulder (closest to the top of the barrel where the eyepiece body attaches). The undercut shoulders oppose each other; one facing up and the other down.

A 1.25” adapter also has at least one shoulder at the top of the 1.25” bore; two more shoulders if it contains a compression ring. The depth of the compression ring groove and the thickness of the brass compression ring determine how much of the compression ring groove shoulder is exposed inside the 1.25” bored adapter. The more a shoulder is exposed, the greater the chance that one of the opposing eyepiece barrel shoulders will catch.

With a smooth eyepiece barrel and a smooth adapter bore, there are only two shoulders that can catch; the bottom of the barrel and the top of the adapter. This can only happen when initiating insertion and represents the first possible catch. Once insertion is started, the wall of the adapter guides the eyepiece in smoothly (depending on clearance). When extracting the eyepiece, there are no opposing shoulders to come into contact with each other.

Adapter thumbscrews are located very near the top of an eyepiece adapter, usually within 1/8”. Adding height to the adapter to place the thumbscrew lower on the eyepiece barrel would, in turn, require more in-travel of the focuser. Since the compression ring is located under the thumbscrew, it is also very near the top of the adapter, inside the 1.25” bore. Almost all compression ring grooves are cut deeper than the thickness of the metal compression ring so that the edges (top and bottom) of the compression ring do not protrude into the path of an eyepiece barrel. If they did, the compression ring itself would cause a catch. But when the groove is deeper than the thickness of the ring, the difference exposes the shoulders of the compression ring groove. That difference creates a larger inside diameter than the 1.25” adapter bore which allows the eyepiece to tilt. The 1/8” of adapter wall above the compression ring is insufficient to keep the eyepiece guided into the adapter. Instead, that rim of the adapter acts as a fulcrum; the eyepiece barrel below is allowed to enter the larger diameter (groove) adjacent to the compression ring; the eyepiece barrel above tilts slightly and the second possible catch occurs when the bottom edge of the eyepiece barrel makes contact with the lower shoulder of the compression ring groove. If the compression ring was located much lower inside the bore, there would be sufficient length for the bore to guide the eyepiece barrel in without a catch. But the thumbscrew, as we know, must be located high on the adapter to avoid additional focuser in-travel. This second catch is why some equipment combinations require that the eyepiece be wiggled or rotated to seat properly in the adapter.

Extracting an eyepiece with an undercut from an adapter with a compression ring may allow a third catch to occur when the lower shoulder on an eyepiece barrel undercut comes in contact with the upper shoulder on a compression ring groove. These are generally considered the most dangerous, because the catch can cause a user to loose grip of the eyepiece just at the moment of extraction resulting in a dropped eyepiece. Extraction catches are exacerbated by other potential issues such as a protruding (deformed) compression ring, very wide, exposed shoulders on the compression ring groove, or excessively deep undercut on the eyepiece barrel.

ADVANTAGES AND PROBLEMS

Barrel undercuts were originally designed to be used with thumbscrews. The mechanical advantage was to provide additional eyepiece security in case the thumbscrew loosened. For that reason, they are often referred to as “safety undercuts.” The value of the barrel undercut only exists if the adapter is facing down, preventing the eyepiece from succumbing to gravity and falling to the ground. There are some situations when adapters/eyepieces do face downward. On Schmidt Cassegrain telescopes, screw-on diagonals can become loose and rotate counter-clockwise, allowing the adapter to fall into an upside-down position. The same can occur to a diagonal with a screw-on nose. And it can happen when the combined weight of a bino-viewer and eyepieces exceed the holding power of the focuser or adapter. Also, eyepieces held in a turret on any kind to telescope are upside down at some point when rotating the turret. An observer may intentionally rotate a diagonal downward to allow a child to observe. And, diagonals on refractor or Newtonian telescopes mounted on an equatorial mount can get into odd positions when trying to observe certain areas of the sky, again, pointing the diagonal or focuser toward the ground. But any diagonal, except the Denkmeier IVB Star Diagonal, if not firmly secured in a focuser, can rotate. These are the primary situations in which an undercut provides an advantage when a thumbscrew is insufficiently tight. For Dobsonians, the focuser is usually held at some angle closer to horizontal than vertical. Unless by accident, it would be very unusual for a Dobsonian adapter to face downward.

Thumbscrew compression rings provide only one benefit; they do not allow the thumbscrew to mark an eyepiece barrel. There are other ways to avoid marring barrels. Nylon or plastic thumb screws, or Nylon tipped metal thumbscrews used in a smooth bore adapter do not mark barrels. Collet type mechanisms do not mark barrels. These alternatives eliminate two shoulders in the adapter, both of which can cause catches.

A catch during insertion or extraction requires a user to move the eyepiece until it is parallel to the adapter bore and perfectly centered so that opposing shoulders can clear one another, allowing the eyepiece to be fully seated or extracted. But this maneuver (usually wiggling or rotating the eyepiece) must take place in the dark or semi-dark for nighttime astronomers. If using an alt/az or Dobsonian mount, targets are often lost and must be re-acquired with a wide-field eyepiece, switching to a higher magnification starts the process again. Losing a target after acquisition several times in a session becomes frustrating. Catches can move the scope so the target is lost, but catches also slow the process of changing eyepieces. When observing double stars, moving to higher magnification means a smaller field of view and mere seconds of time to switch eyepieces and refocus before the target is lost.

Incompatibility between brands of eyepieces and adapters is also responsible for performance related issues. When a thumbscrew or a compression ring does not precisely align with an eyepiece barrel undercut, the thumbscrew/compression ring can hit the shoulder of the undercut. If it hits the upper shoulder, it can lift that side of the eyepiece, tilting the eyepiece in the adapter and preventing registration with the adapter and focuser. This prevents critical focus across the field of view. Tilting eyepieces also adversely affects focus and image merging in bino-viewers.

Not all compression rings are equal. Some 1.25” adapters use a brass compression ring measuring less than 1/4” wide, but some are as much as 3/8” wide. And their location in the adapter bore is not standard. Almost all 1.25” barrel undercuts are close to 1/4” wide but a few newer ones are 9/16” wide. When a compression ring or thumbscrew does not fit into the undercut, the purpose of the undercut (preventing unintended ejections) is defeated. When a wider compression ring spans all of the undercut, a significant percentage of its gripping strength is also defeated. Worse, if a wide compression ring spans only part of the undercut, tightening the thumbscrew can deform a malleable brass ring, forcing part of the ring into the undercut. This can lock an eyepiece in the adapter, requiring special tools to unseat the eyepiece and deformed compression ring.

Tele Vue and Explore Scientific have acknowledged that issues exist with catches and have modified their products in different ways to address the problems. Tele Vue has modified new eyepiece barrel undercuts to include a short bevel at the lower shoulder. They have put the same bevel on the lower shoulder of the compression ring groove. These bevels are designed to work together to eliminate potential catches during insertion and extraction. Think of a marble being dropped into a funnel… the bevel (inside of the funnel) guides the marble to the smaller outlet hole at the bottom of the funnel. The beveled shoulders are designed to slide along an opposing shoulder, keeping the eyepiece centered for insertion or extraction without catching. This remedy was designed specifically to work among various Tele Vue products.

Explore Scientific is using a new eyepiece barrel with an inverted conical taper at the top, adjacent to the eyepiece housing. The taper is designed to eliminate 90 degree shoulders that can catch. In this design, when a typical brass compression ring is closed against the inverted conical taper, the bottom of the compression ring makes first contact with the most shallow part of the taper. Tightening a thumbscrew further, forces a brass compression ring to deform in two directions until it seats against the tapered barrel. To compensate for the malleable qualities of brass, Explore Scientific employed a stainless steel compression ring which is much more rigid and less malleable. When the stainless steel compression ring is tightened, it is difficult to deform with the thumbscrew unless inordinate pressure is applied. This system does function to eliminate extraction catches but introduces new issues. First, only the bottom edge of the stainless steel compression ring is used to grasp the bevel. Second, the bevel is not designed to be used with brass compression rings. And, this remedy does not address insertion catches; the bottom shoulder of eyepiece barrels can still catch on the lower shoulder of the compression ring groove. And, if the eyepiece is not firmly seated in an adapter, the pressure from the compression ring could cause the eyepiece to tilt in the adapter because the deepest part of the taper is at the top of the barrel. The inverted conical taper does work well with a plain thumbscrew because tightening the thumbscrew against the inverted taper pulls the eyepiece in a downward direction (into the adapter) while locking it against the outer wall of the bore in which the eyepiece is held. A collet adapter would hold it well, but would lose its grasping strength over the length of the taper.

To my knowledge, public testing of the comparative effectiveness of these two concepts has not been conducted.

As a result of these issues, some users have relied on home remedies to eliminate problems peculiar to their equipment. Some have found smooth barreled eyepieces that meet their need to avoid catches or lifting/tilting issues. Some have wrapped plastic or metal foil tape around undercuts, filling their voids to make them smooth again, an effort to eliminate shoulders that catch. Some have machined new adapters that do not employ compression rings but rely on a single thumbscrew instead; AGAIN, an effort to eliminate opposing shoulders. Others have purchased older style diagonals and adapters that work better with their newer eyepieces; or, new style adapters, including collet style adapters, that work better with their eyepieces.

Collet adapters do not use a metal compression ring or thumbscrew. Instead, they use a wide, rigid-plastic, split-ring that compresses around the circumference of the eyepiece barrel, applying even pressure. Some collet style compression rings are segmented and use pins on the circumference to grasp the eyepiece barrel. But if the eyepiece has an undercut, the portion of the compression ring covering the undercut loses its friction resistance. A 1/4” undercut reduces the gripping surface area of a 5/8” wide compression ring by 40%. This could be critical if the collet mechanism is holding a heavy eyepiece, bino-viewer, or camera… especially if held parallel to the ground. Gripping strength is based on the coefficient of friction between the eyepiece and adapter. The greater the weight (or in this case, pressure) between two surfaces, the more energy or pressure is needed to initiate movement (static friction). So the tighter a thumbscrew or collet is made, the more resistant to unintended movement the eyepiece, turret or binoviewer becomes. Users typically know this intuitively, adding pressure on thumbscrews that hold eyepieces in a turret more firmly than if the eyepiece is in a Dobsonian focuser or a refractor diagonal… because they know the eyepieces that are upside down in the turret can fall out. Existing collet style adapters may not be fully compatible with dual barrel eyepieces which have an inner 1.25” barrel and an outer 2” skirt, because the skirt rests on top of the collar, preventing full insertion of the 1.25” barrel. Most dual barrel eyepieces are longer and heavier, which makes the partial insertion of the 1.25” barrel even more precarious. Dual barrel eyepieces were not the focus of this study and were not included.

Compatibility of components may rely on close tolerance or special clearance to function properly. But to date, there are no industry-wide specifications to guarantee that eyepiece barrels and adapters will work together.

ADAPTERS AND EYEPIECES USED FOR TESTING

For testing/comparison purposes, I used ten 1.25” adapters. However similar they appear, they all presented different details, found in my descriptions or in Table A (weights & measures), below. Three are distinct because in addition to holding the eyepiece, they provide additional weight to compensate between heavy 2” eyepieces and lighter weight 1.25” eyepieces.

The listed weights and measures for each adapter, were taken by me, using a non-certified home digital scale and non-certified electronic calipers. For convenience and to avoid confusion between fractional inch measurements and decimal inch measurements, I chose to use metric units instead.

1. The Explore Scientific adapter is a new model. It is nicely finished, anodized aluminum and uses a wide, stainless steel compression ring which is a good deal more rigid than brass; the compression ring is quite difficult to remove from its groove. The stainless steel ring should hold its shape very well and it has much better memory than brass. A substantial shoulder is visible at the compression ring groove; both the upper and lower shoulders have a small chamfer. It is threaded to accept 2” filters. This image shows its compression ring groove shoulders for visual comparison to others.

2. The Orion adapter with a wide, brass compression ring is an older model; the outside 2” barrel is smooth (no undercut). This adapter has a very smooth transition between the inner 1.25” bore and the brass compression ring; exposed shoulders are minimal. It is threaded for filters.

3. The Orion adapter with single thumbscrew binding is also older and very similar to the brass compression ring model (#2, above), but has a smooth 1.25” bore with no compression ring. This adapter has a 1/4” undercut on the outside, 2” barrel. The thumbscrew is very small with fine threads. It is threaded for 2” filters.

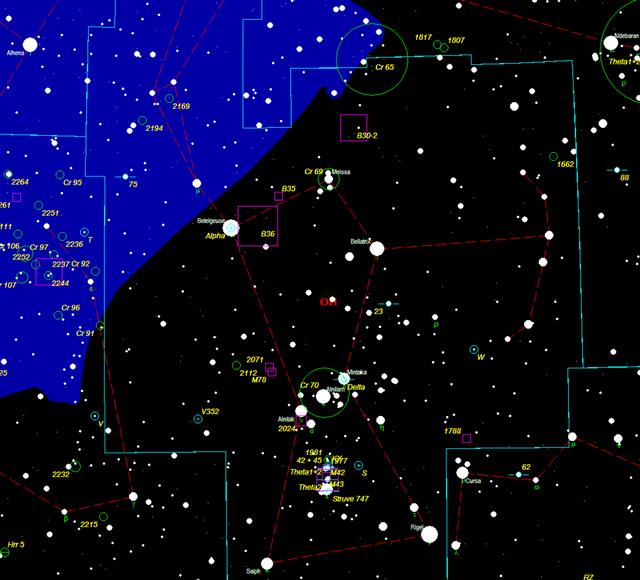

![]() |

4. The Tele Vue Hi-Hat adapter with 1/4” brass compression ring and 1/2” undercut on the outside 2” barrel was purchased 3 years ago and is different from current models which have a bevel cut on the lower shoulder of the compression ring groove (see description of #6, “New Tele Vue Equalizer”). This adapter is aluminum, anodized satin black; it does not have filter threads. The aluminum thumbscrew is captive. Most of this adapter’s measurements mimicked the “Old Tele Vue Equalizer”, #7 below, before it was modified. The photos show the compression ring with exposed shoulders and the captive set screw with the ring removed (see “FINDINGS” for further explanation of the Hi-Hat compression ring groove).

![]() |

| |

![]() |

5. The Astro Tech “MODIFIED” adapter is 4 years old, uses a very wide and rigid (thicker) brass compression ring and a non-captive aluminum thumbscrew in a satin, black anodized aluminum body. This adapter had very substantial shoulders above and below the compression ring. This adapter was shop modified to eliminate the majority of both shoulders by machining a 3/16” long bevel at the bottom shoulder and a larger chamfer at the top shoulder. This was one of two adapters that was so modified prior to this comparison (the “Old Tele Vue Equalizer”, #7, was the other).

![]() |

6. The “New Tele Vue Equalizer” was updated over one year ago, when Tele Vue added: a bevel on the lower shoulder of the undercut on the outside 2” barrel; a bevel to the lower shoulder of the compression ring groove in the 1.25” bore; and a thumbscrew change from a captive 10-24 to a non-captive 8-32. The new thumbscrew is supported by a black metal collar. The Equalizer is bronze and weighs 12 oz. to compensate for weight differences between heavy 2” and lightweight 1.25” eyepieces. It is not threaded for filters.

![]() |

7. The older model Tele Vue Equalizer was manufactured with 90 degree undercuts and it had substantial exposed shoulders (+/- .40mm), similar to the Tele Vue Hi-Hat above (#4). Because it suffered from many catches, I MODIFIED this adapter to replace the shoulders with a bevel in an effort to reduce catches during insertion and extraction. My bevel is more gradual (1/4” long) than the Tele Vue bevel that is incorporated in eyepiece undercuts and adapter compression ring grooves. I gave the upper shoulder a gentle radius to reduce catches during extraction. I purchased this Equalizer about 2004; it is well used. It has no filter threads and the brass thumbscrew is captive. This adapter was one of two adapters so modified, the other being #5, the Astro Tech adapter listed above.

![]() |

8. The Shop Made Stainless Steel adapter was my design, produced in a local machine shop, for use with a stainless steel or a nylon 10-24 tpi thumbscrew, no compression ring or external undercut on the 2” barrel and no filter threads. It was designed to be 14 oz. for balance control when changing from Ethos to lightweight orthoscopic eyepieces.

![]() |

9. The Antares Twist Lock adapter is aluminum and uses a threaded collar to compress the rigid plastic compression ring against an internal bevel. The 5/8” wide compression ring extends to the very top of the 1.25” opening; the eyepiece does not contact any metal during initial insertion. This ring has a shoulder cut on its top, outside edge to allow the collar to seat properly and push the ring down upon the bevel as the collar is rotated clockwise. There is a 2mm gap below the compression ring to allow the ring to be forced down onto the internal bevel during compression. The aluminum barrel below the gap is 11mm wide and 31.8mm in diameter; allowing .05mm clearance for the eyepiece. The adapter is threaded for use with filters. I removed silkscreened labeling from the top of the collar with acetone and chamfered the lower outside edge of the 2” barrel because that edge was quite sharp. The chamfer also eased insertion into diagonal.

![]() |

10. The Blue Fireball Twist Lock adapter is satin anodized aluminum and uses the same principal for gripping an eyepiece as #9 (the Antares model). But the collar on the Blue Fireball completely covers the top edge of the rigid plastic compression ring. All external edges on this adapter are chamfered for smooth handling and the transition between the 5/8” wide compression ring and the lower aluminum barrel inside the 1.25” bore is very smooth; there are no exposed shoulders inside the 1.25” bore. There was a difference between the compression ring construction of this adapter when compared to the ring in the Antares model. And the rate at which the compression ring closed around an eyepiece barrel was slower than the Antares model when tightening the collar.

TABLE A: ADAPTER WEIGHTS & MEASURES

| | weight (oz.) | height of 1.25” extension (mm) | compression ring width (mm) | protruding shoulders (mm) | compression ring material |

| NEW Explore Scientific CR | 3.4 | 9.2 | 6.6 | 1.1 | stainless steel |

| Orion CR | 3.3 | 9.9 | 8.9 | 0.21 | brass |

| Orion Thumbscrew | 3.3 | 9.9 | n/a | n/a | n/a |

| Tele Vue Hi-Hat Aluminum | 3.4 | 15.8 | 4.7 | 0.42 | brass |

| Astro Tech Modified CR | 3.2 | 10.2 | 8.9 | 0.18 | brass |

| NEW Tele Vue Equalizer CR | 11.9 | 16.6 | 4.7 | 0.11 | brass |

| TV Equalizer CR Modified | 12.0 | 15.3 | 4.7 | 0.10 | brass |

| Shop Made SS Thumbscrew | 14.0 | 13.0 | n/a | n/a | n/a |

| Antares Twist Lock | 3.2 | 10.2 | 15.2 | n/a | rigid plastic |

| Blue Fireball Twist Lock | 2.7 | 11.2 | 16.5 | n/a | rigid plastic |

In Table A, “CR” stands for Compression Ring.

“Height of 1.25” extension” is the height of the 1.25” barrel that extends above the 2” barrel stop… this measurement represents the additional focuser in-travel that is needed to compensate for the added height of the adapter.

“Protruding shoulders” is the width of the compression ring groove shoulders, measured from the compression ring to the edge of the exposed shoulder (depth of the groove minus the thickness of the compression ring). I consider these measurements approximate. First, they include hundredths of a millimeter, a very fine unit of measure. Second, I had to take two measurements, subtracting one from the other to achieve the final figure. I measured each one twice to verify my findings… they are very close, but could be off by a few hundredths.

Overall height of the adapters ranged from 10.2mm to 15.8mm. The 2” exterior barrel dimension ranged from 50.6mm to 50.8mm (50.8mm equals 2”). The 1.25” bore of the adapters ranged from 31.80 mm to 31.90mm; most were oversized for proper clearance with the 1.25” (31.75mm) eyepiece barrels.

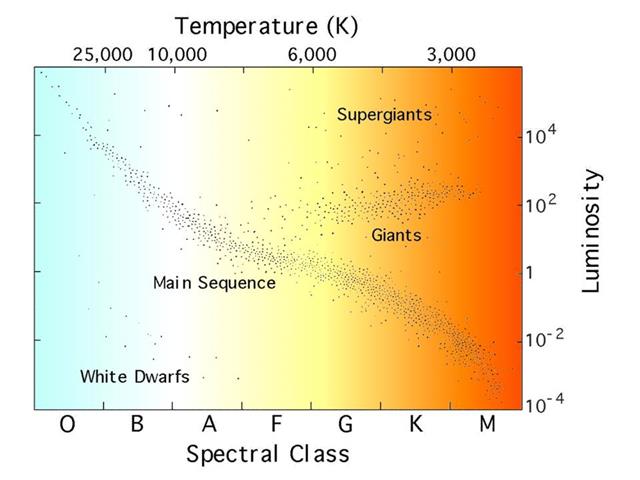

For testing I decided only 4 eyepieces were needed. But one, the Panoptic 24, was used three times; first, with a new barrel (beveled lower shoulder of the undercut), then with the older barrel that had 90 degree undercut, and finally, the older barrel again, but this time with copper foil tape filling the 90 degree undercut. I used a Pentax XO-5 for its more shallow undercut, a Parks GS 30 for its smooth barrel, and a Sterling Plossl for its inverted taper design. Below are photos of the six barrel styles that were used for testing:

TABLE B: EYEPIECE WEIGHTS AND MEASURES

| | weight oz. | undercut to stop (mm) | overall height (mm) | undercut width (mm) | undercut depth (mm) | barrel material |

| Panoptic 24 new bevel | 7.8 | 2.9 | 74.5 | 6.2 | 0.36 | brass/chrome |

| Panoptic 24 old undercut | 7.8 | 2.7 | 74.5 | 6.6 | 0.38 | brass/chrome |

| Panoptic 24 foil wrap | 7.8 | 2.7 | 74.5 | n/a | 0.06 | brass/chrome |

| Pentax XO5 shallow cut | 3.0 | 1.9 | 45.1 | 6.0 | 0.29 | brass/chrome |

| Parks GS 30 smooth | 5.6 | n/a | 82.1 | n/a | n/a | brass/chrome |

| Sterling 30 bevel barrel | 3.4 | 2.0 | 76.6 | 10.1 | +/- 0.7 | anodized aluminum |

In Table B, “undercut to stop” is the distance between the upper undercut shoulder and the bottom of the eyepiece housing which comes to rest against the top of the 1.25” adapter. This short measurement is the width of 1.25” barrel that is above the undercut and is responsible for keeping the top of the barrel centered in the adapter.

The copper foil wrapped undercut was not perfectly level with the 1.25” barrel, leaving a very small gap (0.06mm). But another wrap of the tape would have exceeded the 1.25” barrel diameter, acting like a shoulder to create additional problems.

TESTING

The first test was to determine the number of catches during insertion and extraction. This is represented as two numbers (e.g. “9/5”), the first number representing catches during insertion, the second number for catches during extractions. I quickly decided to restart the tests and include a second criteria that I called “bumps”. I define a catch as a complete stoppage of insertion or extraction, where the eyepiece cannot move further without additional manipulation. I define a bump as the eyepiece barrel or a shoulder making contact with another shoulder and slowing a smooth insertion. Bumps are not as serious as catches because the eyepiece is directed into the adapter bore and seats properly, but the sensation of a bump is different than a completely smooth insertion. There was a range of severity regarding bumps; some were hard enough to move my alt/az mount; others were so light, they were barely perceptible. Bumps of minimal severity are noted with an asterisk. The second set of numbers below the first, represents bumps that occurred during insertion/extraction. Each eyepiece was cycled 50 times in each adapter. The adapter was held in a diagonal, in a refractor focuser, mounted and angled approximately 60 degrees up from horizontal. The angle of the telescope remained the same throughout this testing procedure.

TABLE C: INSERTIONS/EXTRACTIONS WITH 50 CYCLES

(insertion/extraction catches above; insertion/extraction bumps below)

| | 24 Panoptic new with bevel | 24 Panoptic old style undercut | 24 Panoptic with copper wrap | XO5 Pentax undercut | Park GS smooth barrel | Sterling inverted taper |

| Explore Scientific - CR | 33/0 14/34 | 30/26 20/19 | 34/0 14/13 | 4/6 41/43 | 27/0 25/0 | 21/0 29/32* |

| Orion CR | 0/0 catches 35/16 bumps | 13/5 32/31 | 20/0 28/9 | 0/8 24/37 | 19/0 31/0 | 6/0 44/15* |

| Orion TS | 0/0 2/0* | 0/0 0/8* | 0/0 0/0 | 0/0 0/0 | 0/0 0/0 | 0/0 0/0 |

| Tele Vue Hi-Hat CR | 23/0 24/35 | 10/31 catches 29/17 bumps | 24/0 23/0 | 4/0 23/11 | 22/0 28/0 | 10/0 40/26* |

| Astro Tech CR-Modified | 0/0 42/9 | 0/4 31/38 | 0/0 47/0 | 0/19 2/26 | 9/0 34/0 | 0/0 23/10* |

| Tele Vue Equalizer CR | 0/0 44/8* | 0/38 40/10 | 0/0 catches 42/6 bumps | 0/24 0/26 | 5/0 32/0 | 0/0 38/12* |

| TV Equalizer CR-Modified | 4/0 40/12* | 0/7 11/36* | 0/0 40/7* | 0/0 12/50 | 2/0 26/0 | 0/0 32/8* |

| Taylor Made SS - TS | 0/0 0/0 | 0/0 0/4* | 0/0 0/0 | 0/0 catches 0/0 bumps | 0/0 0/0 | 0/0 0/0 |

| Antares Twist Lock | 0/0 0/0 | 0/0 0/0 | 0/0 0/0 | 0/0 0/0 | 0/0 0/0 | 0/0 0/0 |

| Blue Fireball Twist Lock | 0/0 0/0 | 0/0 0/0 | 0/0 0/0 | 0/0 0/0 | 0/0 catches 0/0 bumps | 0/0 0/0 |

In Table C, “CR” stands for Compression Ring; “TS” stands for Thumb Screw

In Table C, * (asterisk) denotes bumps that were consistently very slight or barely perceptible

To read this table, select an adapter and read across to see how it performed with various eyepieces; or, select an eyepiece and read down to see how it performed with various adapters. Please be mindful of the two adapters that were modified before testing.

The second two-part test was to determine if an eyepiece was securely held by the adapter when turned upside down. For this procedure, I used moderate pressure to tighten the thumbscrew or collar of the twist lock adapters and held the outside of the adapter rotating it upside down. All eyepiece/adapter combinations passed. Then, holding only the adapter, I brought the adapter down sharply until my wrist stopped abruptly in my opposite hand (think of a clap). This tested the gripping strength of the adapter under circumstances which are unlikely to occur; all adapters also passed this test.

The third test was designed to check the effectiveness of a barrel undercut at preventing an unintentional eyepiece ejection. I placed the eyepiece in a mounted diagonal/adapter, inserted and seated the eyepiece and then tightened the thumb screw to hold it in place… upside-down.

I marked the thumbscrew and the adapter for a registration point and then slowly turned the thumbscrew counter-clockwise to loosen it. When the eyepiece released and dropped, I stopped rotation of the thumbscrew and used a protractor to determine the degrees of rotation, recorded in the boxes of Table D. I performed 5 cycles for each eyepiece with the telescope in a horizontal position with adapter and eyepiece held vertically, pointing directly down. I repeated the test with the telescope held at a 45 degree angle. However, the eyepiece would release and slide to the end of the adapter where it stopped in most adapters (see FINDINGS for detailed explanation). The degree of thumbscrew or collar rotation required to fully release the eyepiece at zero or 45 degrees was consistent. Recorded degrees are an average of 5 cycles +/- 10 degrees.

TABLE D: EYEPIECE BARREL UNDERCUT EFFECTIVENESS

(degrees of thumbscrew rotation required for eyepiece to slip out of focuser)

| | 24 Panoptic new with bevel | 24 Panoptic old style undercut | 24 Panoptic with copper wrap | XO5 Pentax undercut | Park GS smooth barrel | Sterling inverted taper |

| Explore Scientific CR | 230 | 110 | 60 | 60 | 20 | 180 |

| Orion CR | 110 | 110 | 60 | 50 | 20 | 180 |

| Orion TS | 320 | 340 | 80 | 220 | 30 | 380 |

| Tele Vue Hi-Hat CR | 200 | 210 | 50 | 110 | 20 | 180 |

| Astro Tech CR Modified | 60 | 60 | 60 | 60 | 20 | 240 |

| New TeleVue CR Equalizer | 200 | 210 | 60 | 160 | 20 | 240 |

| TV Equalizer CR Modified | 210 | 220 | 60 | 40 | 20 | 180 |

| Taylor Made SS - TS | 160 | 170 | 50 | 130 | 20 | 160 |

| Antares Twist Lock | 20 | 20 | 20 | 20 | 20 | 20 |

| Blue Fireball Twist Lock | 20 | 20 | 20 | 180 | 20 | 270 |

The numbers in this table are degrees of rotation of the thumbscrew or collar required to release an eyepiece; one revolution being 360 degrees. Degrees were rounded to the nearest 10. Numbers ranging from 100-340 indicate that an eyepiece barrel undercut was accessed by the thumbscrew or compression ring, allowing the safety feature of the undercut to be effective. Numbers from 20-40 indicate that the undercut was not accessed, and therefore, served no purpose; except for the copper foil wrapped barrel, in which the copper tape was somewhat compressed, especially by the bare thumbscrew. To figure out what fraction of a revolution the degrees represent, divide 360 by the posted number; to figure out what percentage of a revolution the degrees represent, divide the posted number by 360… and move the decimal point; e.g., 20 degrees is 5.5% or 1/18 of a revolution, before the eyepiece was released. The Orion thumbscrew adapter utilized a very small thumbscrew with fine threads (probably 6-40 tpi or a metric equivalent) which required more rotation to move the screw, compared to all other screws, which ranged from 8-32 tpi to 10-24 tpi.

Ergonomics are important when using equipment in the dark, so I conducted a short evaluation in a dark closet to test function of adapter styles; a thumbscrew/compression ring and the two twist lock adapters. I only used one eyepiece during this trial with 20 insertion cycles for each adapter. Then I tried the same thing while wearing some fleece gloves. During this process I was struck by the difficulty I had in changing the eyepiece in the Blue Fireball adapter because it required 2-3 hand movements to lock or unlock the collar. Why? Because my fingers were only able to rotate the collar about 65 degrees each time I grasped it. Remember that I found a distinction between the Blue Fireball and Antares twist lock adapters… the Antares model, which employs a steeper bevel angle, opened and closed with one twist… occasionally needing an extra short twist to lock the eyepiece. The Blue Fireball requires at least 2 twists, sometimes needing a third. This procedure was complicated with gloves, requiring more deliberate movement to be successful. I preferred the Antares over the Blue Fireball mainly for this issue. In practice, I use the Blue Fireball for only one purpose… to hold my heavy 1.25” Barlow; I never remove it from the Barlow. For that purpose, it serves quite well. Compared to a thumbscrew, the collar seemed a little more cumbersome, especially if wearing gloves. Of course, my years of experience with thumbscrews has probably tilted my bias on this issue… as they say, your mileage may vary.

FINDINGS

By the time I got about 2/3 of the way through the test for catches, I discovered that if I changed the altitude axis of the telescope and therefore, the angle of the adapter, I could change the number of catches or bumps. Thankfully, I had kept the telescope at the same relative angle (about 60 degrees above horizontal) during my testing, so that influence did not skew results of my 3,000+ eyepiece insertions. But here, you can interpret the information to mean that different telescopes may in fact yield significantly different catch results, simply because of how their focuser is mounted or angled for use. I found that if an eyepiece is inserted vertically (straight down, as if the adapter is on a table), there are fewer catches than if the adapter is horizontal or at a 45 degree angle. My mechanical experience tells me that the weight and length of the eyepiece should also influence numbers or severity of catches because of tilting the barrel. There are lots of variables.

The function of grasping an eyepiece needs no explanation. But how it is handled during insertion or extraction may play a role to cause catches. Grasping an eyepiece from above or from the side, with the whole hand or just 2 fingers, causes different muscle interaction. Holding an eyepiece one way may result in gross movement of the arm and hand for insertion; whereas, grasping it with fingers may use more finger movement during insertion. Fine motor skills are also correlated to vision and depth perception, which is effected during darkness. These factors could result in higher or lower numbers of catches between individual performance.

The Explore Scientific had more catches than any other adapter. One very likely answer lies in Table A, which shows that it has the biggest exposed shoulders (1.1mm) at the compression ring groove. Its exposed shoulders are more than twice as wide as the next closest adapter, the TV Hi-Hat (.42mm). The other 4 compression ring adapters have exposed shoulders ranging from .21 to .10mm and the number of catches they suffered was correspondingly lower.

During initial testing of the Blue Fireball twist lock adapter, I detected many more “bumps” than the Antares twist lock. I measured the inside diameter of the aluminum barrel below the plastic compression ring in both adapters: Blue Fireball = 31.83mm vs. Antares = 31.99mm. The closer tolerance to the eyepiece barrel diameter (less clearance) probably resulted in the eyepiece barrel making contact with the aluminum bore below the plastic compression ring in the Blue Fireball. Later, I also discovered that the collar on the Blue Fireball was unscrewed much more than the Antares collar, allowing the compression ring to expand more than the diameter of the lower aluminum barrel. I considered the first test results of the two twist lock adapters flawed. So I re-tested them for catches and bumps after adjusting their collars equally; after loosening the adapters sufficiently to remove the eyepiece, I opened each one an additional 180 degrees. All insertion catches and bumps disappeared. I considered the results of my first test to be the result of user error. Table C was corrected to reflect the second test results.

I also found that the collet system has some limitations, such as, when holding dual-barrel eyepieces. In all cases that I tried, the 2” skirt prevented the 1.25” barrel from inserting very far. This reduced the surface area being gripped and created the need for additional focuser in-travel. This seemed not to be a good match for long, heavy eyepieces in particular. Using a 10mm Ethos, and tightening the collar as tight as I could, I could still pull the 1.25” barrel from the collet adapters… without using “brute” strength. And, as eyepieces were each inserted 250 cycles, the Blue Fireball adapter accrued an accumulation of very fine, dry residue between the plastic compression ring and the anodized aluminum bevel. It cleaned out with the sweep of a finger, but the residue was from micro-particles being abraded from friction between the plastic compression ring and the anodized bevel inside the adapter. So, composition of the compression ring will be a factor concerning wear qualities. The Antares and Blue Fireball twist lock adapters are on the least expensive end of collet style adapters (retailing new for about $30).

The Tele Vue Equalizer with a bevel on the lower shoulder of the compression ring when used with the new Panoptic barrel with a bevel had zero insertion and extraction catches; and the “bumps” were very minor. The remedy works perfectly; but only when new barrels are used with new adapters. When the new adapter was used with an old Panoptic barrel, or Pentax eyepiece with 90 degree undercuts, there were still many extraction catches. That is because nothing was done to change the cause of extraction catches between the old style undercut and the upper shoulder of the new compression ring. To make the new Tele Vue remedy work properly, you must use new eyepieces or barrels and new adapters. The fix definitely works, it’s just really expensive if you already own older models of Tele Vue adapters and eyepieces. This remedy was developed to work specifically within the Tele Vue family of products; there is no guarantee it will perform the same with eyepieces or adapters from other manufacturers because there is no industry standard, that I am aware of, when it comes to undercuts, compression rings, bevels and chamfers.

When I modified an older Equalizer on my lathe, adding a bevel to the lower shoulder of the compression ring groove, I also put a radius on the upper shoulder. That radius reduced extraction catches in the older TV Equalizer from 38 to 7, using a TV eyepiece with 90 degree undercuts. It was not a perfect solution, but it helped significantly to reduce catches when using an old style barrel.

Tele Vue eyepieces use a slight (about 20 degree) bevel on the bottom of their eyepiece barrels with a very small chamfer on the outside edge. Pentax eyepieces use a long 80 degree chamfer on the bottom edge of their eyepiece barrel, which slides past 90 degree shoulders most of the time. Table C demonstrates the effectiveness of Pentax barrels at eliminating a large percentage of insertion catches compared to the Tele Vue eyepiece when used in the same, older adapters with compression rings.

The Pentax barrel undercut is not quite as deep as the undercut on a Tele Vue eyepiece (Table B). It’s likely that the slightly more shallow undercut did play a part in reducing the total number of extraction catches when compared to the Panoptic 24 with 90 degree undercut. It is a close call and a larger sampling is needed to know for sure.

Thumbscrew adapters without a compression ring (smooth inner bore) and twist lock adapters (which have a very smooth transition between compression ring and inner bore), were consistent in the elimination of catches, both insertion and extraction. Why? Because they eliminated opposing shoulders that cause the catch in the first place.

Eyepiece barrel undercuts can possibly cause a catch during insertion, but ONLY if there is sufficient clearance for them to tilt when their barrel is inserted 3/4 of its length into an adapter. When the lower part of the barrel, below the undercut, is inserted that far, there is generally insufficient clearance to allow the eyepiece barrel to tilt enough to cause a catch between the top of the adapter and the upper edge of the undercut. If the compression ring in the adapter is catching on the undercut when the thumbscrew is fully released, then the compression ring is probably deformed and needs repair or replacement. The brass compression rings must seat properly in their groove to avoid catches with an undercut.

The Parks GS 30 eyepiece with a smooth barrel has a 45 degree chamfer on the bottom of its barrel; the width of that chamfer is .96mm. The Pentax XO-5 has an 80 degree chamfer that is 2.35 mm wide. The Pentax provides a wider chamfer at a greater angle which slides past 90 degree shoulders more effectively. Take a look at Table C and compare catches between these two barrel styles. Please note that the catches were limited to insertion catches using the smooth barrel; the bottom edge of the barrel was catching on the lower shoulder of the compression ring groove during insertion. Details such as the Pentax chamfer can play a significant role in reducing catches.

The 3 year old TeleVue Hi-Hat with 90 degree compression ring groove, and captive aluminum thumbscrew presented a special issue that I discovered late in testing. TeleVue is the only adapter that presents a captive thumbscrew, a “value added” feature that prevents losing a thumbscrew at night. But the captive thumbscrew does not fully retract beyond the wall of the compression ring groove because it is annealed on its edges to prevent unscrewing beyond that point. With the brass compression ring covering the end of the thumbscrew, the exposed shoulder of the compression ring groove is about 1/2 the width when compared to the same shoulder on the opposite side, where the split ends of the brass ring are located. Removing the brass ring, I could feel the slightly raised end of the captive screw, even though the screw was fully retracted to its stopping point. In the new Equalizer, that issue has been eliminated, with a non-captive screw which fully retracts from the groove. Loss of the screw in that new Equalizer is subverted by the longer metal collar through which it must be unscrewed… requiring many full revolutions. I believe this change to eliminate the captive screw was made so that the brass compression ring could set flush with the shoulder of the bevel, around the complete circumference of the compression ring groove. If the captive screw remained, it would have forced the edge of the compression ring into the path of the eyepiece.

The third test I conducted was initially designed to test the effectiveness of barrel undercuts in preventing unintended ejections… which is their sole purpose. It did show that they do their job, but only if the thumbscrew or brass compression ring actually enters the undercut. And, therein, lies the problem. Of the adapters I tested, only the Tele Vue compression rings and the two single thumbscrew adapters actually seated in the undercuts of the 1.25” Tele Vue and Pentax eyepieces. If you return to Tables A & B and look at the compression ring width compared to the width of the undercuts you will see the problem. The Explore Scientific was close in width, but its placement inside the adapter is very slightly different than the Tele Vue compression ring. In the Explore Scientific adapter, the top of the compression ring is 2.9mm from the top of the adapter. In the TV adapter, the top of the compression ring is 4.0mm from the top of the adapter. That 1.1mm difference means that only about 1mm of compression ring width is actually gripping the eyepiece barrel; the remainder of the Explore Scientific compression ring is at rest over the void of the eyepiece barrel undercut on Tele Vue and Pentax eyepieces. Another example is reflected in Table D, as the Astro Tech thumbscrew required 60 degrees of rotation to release eyepieces with an undercut. The width of its compression ring exceeds the width of the undercut, so it cannot grip the eyepiece where the undercut exists. I suspect its compression ring was partially entering the undercut, forced slightly by tightening the thumbscrew. When used with the smooth barrel of the GS 30, the Astro Tech thumbscrew only required 20 degrees of rotation to release. The Orion and Astro Tech compression rings spanned all undercuts, but their wide compression rings provide slightly more contact area when compared to the Explore Scientific compression ring. Their wide compression rings, however, defeat the purpose of the undercut.

The undercut validation test vividly illustrated why catches occur between eyepiece barrels and compression ring grooves when the adapter was held at an upside-down 45 degree angle. I did not report the results of thumbscrew release tests at 45 degrees because they were all so different. When the adapter was held at an upside-down 45 degree angle and the thumbscrew was slowly released to reduce its grip on the eyepiece barrel, in the majority of releases, the eyepiece slid out until the bottom of its barrel came into contact with the compression ring inside the adapter. Then the eyepiece would stop and would not drop from the adapter unless I purposely moved it or I tilted the telescope back up to zero degrees so that the adapter was once again, pointed directly down. This sequence demonstrated, in reverse, how and why catches occur. The more the eyepiece slid out of the adapter, the more it could tilt. When the end of the barrel reached the compression ring, in nearly all cases, it stopped, with the edge of the barrel resting against the compression ring. The lip of the adapter acted like a fulcrum; the extended weight of the eyepiece pulling down, lifting the end of the barrel inside the adapter. This was the test I was actually looking for to prove the cause of insertion catches. It just happens to be shown in reverse with this test.

The results of the 45 degree test were too varied for me to report with any confidence. A few eyepieces did drop out in one smooth movement when used with some of the smooth adapters, but not all. Some eyepieces hit the compression ring and popped out. I’m sure that the coefficient of friction between the eyepiece and the adapter played a part in the variety of results, with brass, polished chrome, machined stainless steel and plastic all playing their role.

The modified adapters, TV Equalizer and Astro Tech, were modified on my lathe using carbide hand tools that I fabricated. The modifications turned out well, considering I was not using a compound cross-slide tool holder. I’m an experienced wood turner and I have spun non-ferrous metals by hand on my lathe. In tests, the modifications performed about as well as the new TV Equalizer with the included bevel. They are not a perfect solution for insertion catches, but they help to drastically improve performance by eliminating most catches caused during insertion and reducing the severity of those catches that persist. This modification can be made at a machine shop for a service charge. The exposed shoulder can be eliminated with the bevel, but enough of the shoulder must remain to support and hold the compression ring in place.

From a mechanical standpoint, the inverted taper of the Sterling eyepiece invites problems when used with most compression ring adapters that use a thin brass ring. But in use, it works quite well as long as the thumbscrew is not over-tightened. It did eliminate all extraction catches and was able to reduce the number of insertion catches over some other barrel types. This eyepiece did not belong to me, so I was careful not to use much pressure on the thumbscrews, but pressure was sufficient to hold the eyepiece. On the last test, to determine if the undercut prevented an unintended ejection, I found that the inverted taper did work as well as the 90 degree or bevelled undercut. While it was upside down, I could see the eyepiece gently slide down along the taper as the thumbscrew or compression ring released pressure. Three times during this test, while paired with the Blue Fireball adapter, the Sterling did not fall free of the adapter. The eyepiece is very light weight and did not overcome the friction resistance of the plastic compression ring. It is possible that the plastic used in the compression ring of the Blue Fireball adapter is more compliant than that of the Antares unit, allowing a slight or temporary deformation. The Antares required only 20 degrees of rotation before releasing the eyepiece; the Blue Fireball required 270 degrees of rotation… a very significant difference, indicating that the Blue Fireball compression ring was probably forced into the inverted taper.

The use of metal foil tape to fill the 90 degree undercuts on the Panoptic 24 was proven effective in eliminating extraction catches. But filling the undercut also eliminates its only positive attribute… providing a safety mechanism for loosened thumbscrews. If you do not care about the safety issue, filling the undercut works very effectively to eliminate insertion catches when used with compression ring adapters. The 1/4” copper foil tape costs about $10-$15 per roll for enough tape to apply to dozens of eyepiece barrels. Its durability appears quite good as long as it is not used with a plain thumbscrew. Compression rings of all types seem to work very well with the tape filled undercuts. I had to trim about 1/16” off of the edge to apply it to the Pentax eyepiece because of its more narrow undercut, but good sharp scissors are sufficient to cut the foil tape. Application is quick, taking about 5 minutes per eyepiece. Tape filled undercuts also eliminate the concern of mis-matched compression rings being deformed over partially covered undercuts. The only concern about such a remedy is off-gassing from the tape adhesive. Most metal tapes use acrylic adhesive; the metal foil averages 1.5-4 mils thick; the adhesive adds another 1.5 mils. The amount of off-gassing released by such a small amount of adhesive should have no effect on an optical system. And off-gassing primarily occurs during initial exposure to the air, when the tape backing is removed to expose the adhesive. This is a very a trivial issue.

CONCLUSIONS

The test for catches was quite revealing to me. When a bevel was placed on the lower shoulder of the eyepiece undercut (extraction) AND on the lower shoulder of the compression ring groove (insertion), as demonstrated by new Tele Vue products, the problem of catches in general, was eliminated. This was confirmed by the difference in performance with the three Tele Vue adapters in use with the various eyepiece barrels. The older aluminum Hi-Hat with 90 degree shoulders on the compression ring groove, when used with 90 degree eyepiece barrel undercuts, suffered many catches. For certain, this Tele Vue remedy shows a remarkable improvement. There was a sensation of a “bump” but it was very well controlled and lightly perceptible. With unmodified adapters/eyepieces which have 90 degree shoulders, there were high numbers of catches and the bumps were much more severe. And, on the two adapters that I modified before initiating the test (Astro Tech and the old Tele Vue Equalizer), the results were very similar to those of the new-style adapters with a bevel. But the Tele Vue remedy does not yet include older Tele Vue products; they have not yet offered new replacement barrels for older eyepieces. And, to be completely effective for both insertion and extraction catches, both the eyepiece barrel and the adapter must be used together.

Some of the possible remedies for compatibility issues between eyepiece barrels and adapters have already been discussed. This is a list of those possible solutions, but they all depend on your current equipment, your personal needs, budget and preferences… each of them relates to elimination of opposing 90 degree shoulders:

Insertion-Only Catch Remedies:

1. In your 2” to 1.25” adapter with a metal compression ring, a bevel can be machined into the lower shoulder of the compression ring groove, eliminating the 90 degree shoulder. Very effective; moderate cost.

2. When selecting eyepieces, ensuring that they have a large, steep bevel on the bottom can greatly reduce or eliminate insertion catches. Moderately effective; no cost

3. Most eyepiece barrels can be removed, taken to a machine shop and machined to create a steep, wide bevel on the bottom edge (similar to Pentax barrels). This removes chrome finishes to reveal the base metal. Moderately effective; moderate cost.

Extraction-Only Catch Remedies:

1. Metal foil tape to fill barrel undercuts is inexpensive, easy to apply and very effective at eliminating extraction catches. Filler tape should not be used with single thumbscrew adapters (those without a metal compression ring). Very effective; inexpensive.

2. Existing eyepiece barrels can be machined to include a bevel on the lower shoulder of the undercut. This removes chrome finishes to reveal the base metal. Very effective; moderate cost.

3. By machining a radius on the upper shoulder of the compression ring groove (just below the top of the adapter) it will help to eliminate many, if not most, extraction catches. Moderately effective; moderate cost.

Insertion AND Extraction Catch Remedies:

1. Tele Vue has successfully modified their eyepiece barrels and adapters to incorporate bevels that eliminate insertion and extraction catches. The cost is high to replace existing eyepieces and adapters. Purchasing just the adapter will eliminate insertion catches. Purchasing only eyepieces will eliminate extraction catches. They are designed to positively work only within the Tele Vue line of products. There is no guarantee that they will work with other makes. And, these improvements are currently only available in two models of the Hi-Hat adapter, one aluminum version and one bronze version (the Equalizer). Tele Vue has not yet incorporated bevels in 2” diagonals, flat top adapters, or the Paracorr (neither 2” nor 1.25” adapter). This remedy does not resolve issues for thousands of eyepieces and adapters already sold. Very effective; very costly.

2. Using an old adapter with smooth inner bore and single set screw can eliminate both insertion and extraction catches when used with all brands of eyepieces having a smooth barrel OR an undercut. It is simple and effective. If an old adapter uses a metal thumbscrew, it can be replaced with a Nylon or plastic thumbscrew to prevent marring your eyepieces. If needed, a second thumbscrew hole can be drilled & tapped. Cost is about $15 for an old adapter on the used market and another $1 for a plastic thumbscrew. Very effective; minimal cost.

3. Custom adapters can be made at a local machine shop to meet your own specifications. If you need a heavy adapter to compensate for weight when switching from two inch, 24-oz. eyepieces to 2-oz. orthoscopic eyepieces, you can have an adapter made of bronze or stainless steel to meet your exact demands. Lightweight adapters can be made of aluminum. The cost of materials is nothing compared to the machinist’s time, so be prepared. One-off production comes at a price; think in the range of $200 to make one adapter. Making 3 or 5 isn’t much more expensive and you might sell them to friends, reducing the per unit cost to $50. Very effective; moderate cost.

4. Twist lock adapters can be used instead of thumbscrew adapters; they eliminate all catches and are compatible with all 1.25” eyepiece barrels. Their collet style mechanism works smoothly and is strong. They eliminate opposed shoulders and are simple to manipulate. Look for twist lock adapters that work smoothly and close/open rapidly. They are light weight and low profile, but their gripping strength is compromised with dual barrel eyepieces. They range in price from $30 to $100. Very effective; moderate cost.

It has been suggested that manufacturers who produce eyepiece barrels with an undercut, supply a metal split ring intended to fill the undercut; those users who prefer the safety of the undercut could remove the ring; those who prefer to eliminate catches could leave the ring in place on the barrel. This seems like a brilliant solution to eliminate extraction catches. This solution, however, has no bearing on insertion catches, which require a separate remedy if used with a metal compression ring adapter.

I do not think it necessary to rank the adapters or eyepiece barrel types; some combinations work together well, while others do not. And each user has their own level of tolerance concerning catches or bumps. I recommend you look at Table C and D to see what works best to suit your needs. The tests were simple and repeatable. You can try them yourself.

Over the past decade, there has been much said and written about barrel undercuts; many positive; many negative. But there are few instances of complaints or compliments about metal compression ring adapters which appear to present more than half of the problems concerning catches. My experience with this test has shown that eyepiece barrels and adapters must work together fluidly to present the best possible outcome. Test results in Table C, show that some combinations do not meet any parameters for my use. I think others might find these results useful, especially if considering a new diagonal/adapter. At the very least, this report has provided information so that the right questions can be asked. To fix a problem, you must first understand the problem. I purposely did not test 2” diagonals. But much of my findings can be extrapolated from 1.25” to 2” designs. The same principles apply, although the remedies may be entirely different.

I find that the historical progression of changes in eyepiece barrels and adapters has served only to complicate a simple mechanism that actually performed very well in the beginning. Each new change, created to provide a “value-added” feature, resulted in more issues that needed to be solved… add an undercut to a barrel for safety then all thumbscrews must align perfectly with the undercut; add a compression ring to prevent marring, then all undercuts and compression rings must align and be of compatible size; prevent catches caused by the undercut or compression ring by adding bevels or chamfers; create a new style barrel to fix catches, but ignore that the barrel is not compatible with common compression rings, then change the compression ring material so the barrel will perform, but without considering compatibility within the industry. Clearly, there is need for industry standards. The current, proprietary efforts do not span the industry and guaranteeing compatibility only within a manufacturer’s own line of products is an unsatisfactory solution for most consumers.

During testing, nothing was superior to my sense of touch than the smooth barrel of the Parks GS 30 being inserted in the smooth barrel of the Orion (single thumbscrew) or the stainless steel adapter… no catches, no bumps. But my tastes have always preferred simple over more complex designs. This is opinion and can be overlooked. But Table C does corroborate my preference, showing zero catches and bumps for the simple union between smooth barrel and smooth bore, even with an old, inexpensive Orion thumbscrew adapter. It would be so easy to make and supply a quality adapter made in this fashion, perhaps, with a Nylon-tipped, metal thumbscrew as the only upgrade. Simple insertion; simple extraction. No undercuts. No compression rings. No shoulders. No bevels. No problems.

This testing process revealed that eyepiece barrel undercuts and adapter compression ring grooves are responsible for extraction catches. Eyepiece barrel ends and compression ring grooves are responsible for insertion catches. Removing only the barrel undercut eliminates extraction catches. But removing only the metal band compression ring eliminates both insertion and extraction catches.

The new collet type adapters, often referred to as twist lock adapters, could transcend the metal compression ring of the past. They eliminate internal 90 degree shoulders, grip an eyepiece well and are simply reliable. In use, they render the barrel undercut a relic, removing any purpose it formerly served. So perhaps, the undercut will also disappear one day.

My wish is that you use the information contained in this material to help find a combination that ends frustration and brings joy during your time under the stars. Clear Skies!

I purchased the Astrotrac TP3065 pier because of its carrying capacity and design. The pier performs well, is stable, well made and has a padded shoulder carrying bag. It can also carry a heavy load. I can run the power lines for the Astrotrac, my camera and USB cable for my camera through the interior of the pier to reduce wire clutter. I discovered I can increase its stability by placing 10 to 15 pounds of weight inside the pier when in use. Info here:

I purchased the Astrotrac TP3065 pier because of its carrying capacity and design. The pier performs well, is stable, well made and has a padded shoulder carrying bag. It can also carry a heavy load. I can run the power lines for the Astrotrac, my camera and USB cable for my camera through the interior of the pier to reduce wire clutter. I discovered I can increase its stability by placing 10 to 15 pounds of weight inside the pier when in use. Info here:

Fig. 5-1: Green flash and Santa Barbara Island, California. Note the island's ends are upturned from the inferior mirage that helped create the green flash.

Fig. 5-1: Green flash and Santa Barbara Island, California. Note the island's ends are upturned from the inferior mirage that helped create the green flash. Fig. 5-2: Water in billions of tiny droplets refracts and disperses sunlight into a spectrum, the familiar to everyone natural phenomenon of the rainbow. Rainbow and farmhouse, Pagosa Springs, Colorado.

Fig. 5-2: Water in billions of tiny droplets refracts and disperses sunlight into a spectrum, the familiar to everyone natural phenomenon of the rainbow. Rainbow and farmhouse, Pagosa Springs, Colorado. Fig. 5-3: Refraction separates or disperses sunlight into different colors as well as distorting shape and changing the sun's position in the sky. Atmospheric dispersion of the solar disk into separate colored images is too small to be seen by the eye under normal circumstances.

Fig. 5-3: Refraction separates or disperses sunlight into different colors as well as distorting shape and changing the sun's position in the sky. Atmospheric dispersion of the solar disk into separate colored images is too small to be seen by the eye under normal circumstances. Fig. 5-4: A mirage magnifies the size and brightness of the green rim to make the green flash visible during the brief interval after most of the sun has set but before the rim itself has set.

Fig. 5-4: A mirage magnifies the size and brightness of the green rim to make the green flash visible during the brief interval after most of the sun has set but before the rim itself has set.